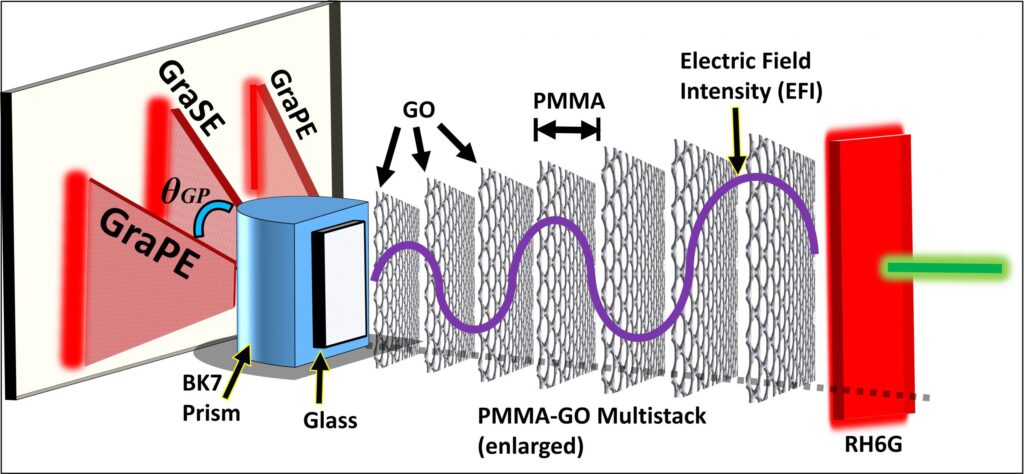

The SSSIHL STAR Lab Research team, led by Asst. Professor Dr. Sai Sathish Ramamurthy, has published a new paper in ACS Applied Materials & Interfaces that explores the use of a novel metal-free, graphene oxide-based photonic crystal framework (GraSP engineering) for Biosensing application. It enhances the performance of plasmonic materials and overcomes Ohmic losses in metals.

New GraSP Engineering to Help Enhance the Performance of Sensing Technologies

Identifying the Issue

- Sensors are of wide-spread use in industrial processes, public health control, homeland security, safety and monitoring

- Plasmonic materials made of metal nano-architectures are world-wide used for sensor technology development. However, their performance is plagued by inevitable intrinsic Ohmic losses, that impede the performance any sensing platform.

- As a result, there is constant hunt for alternative material technology development for global market sensor industries

Objective of the Research

- Identifying the root cause which leads to Ohmic losses

- Finding a cost-effective non-metal-based solution to minimize/stop the Ohmic losses and improve the performance of plasmonic materials, which in turn translates into greater efficiencies for the industries offering solutions based on sensing technologies

- Explore the possibility of the solution aiding in improving the overall sensitivity and specificity by 3-4 times as compared to existing metal-dependent sensor techniques

Who should read this?

Anyone in the industry, working directly or indirectly on sensor development or sensing related technologies including, security, surveillance, monitoring, environmental safety monitoring, medical technologies, and disease diagnostics.

GraSP Engineering – A Eureka moment for the future of Sensing technologies

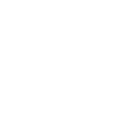

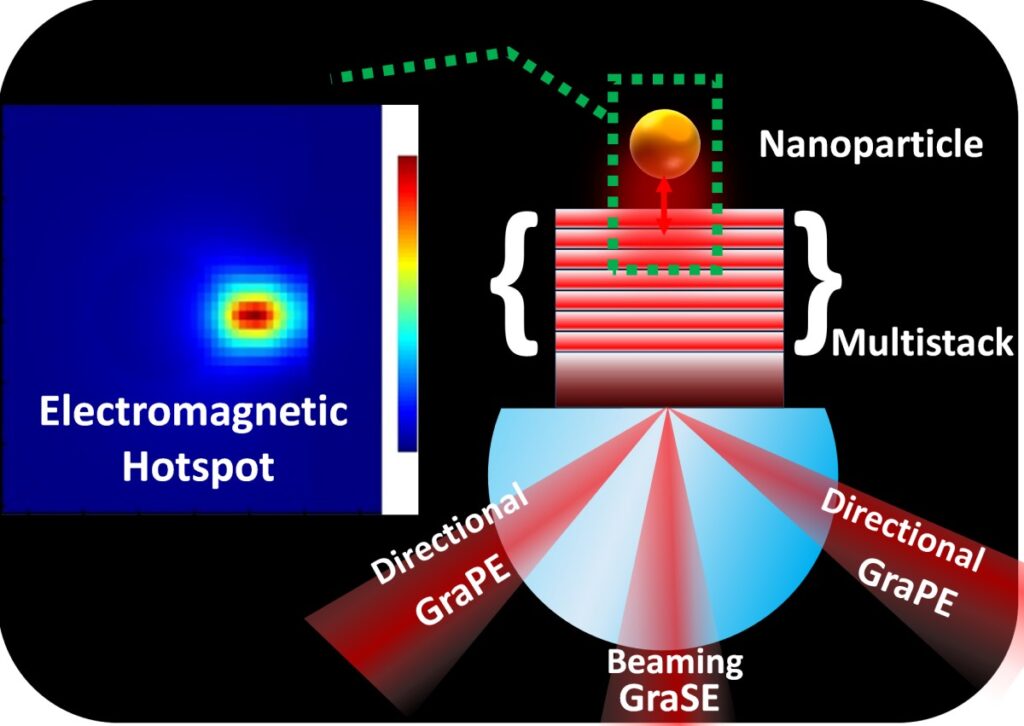

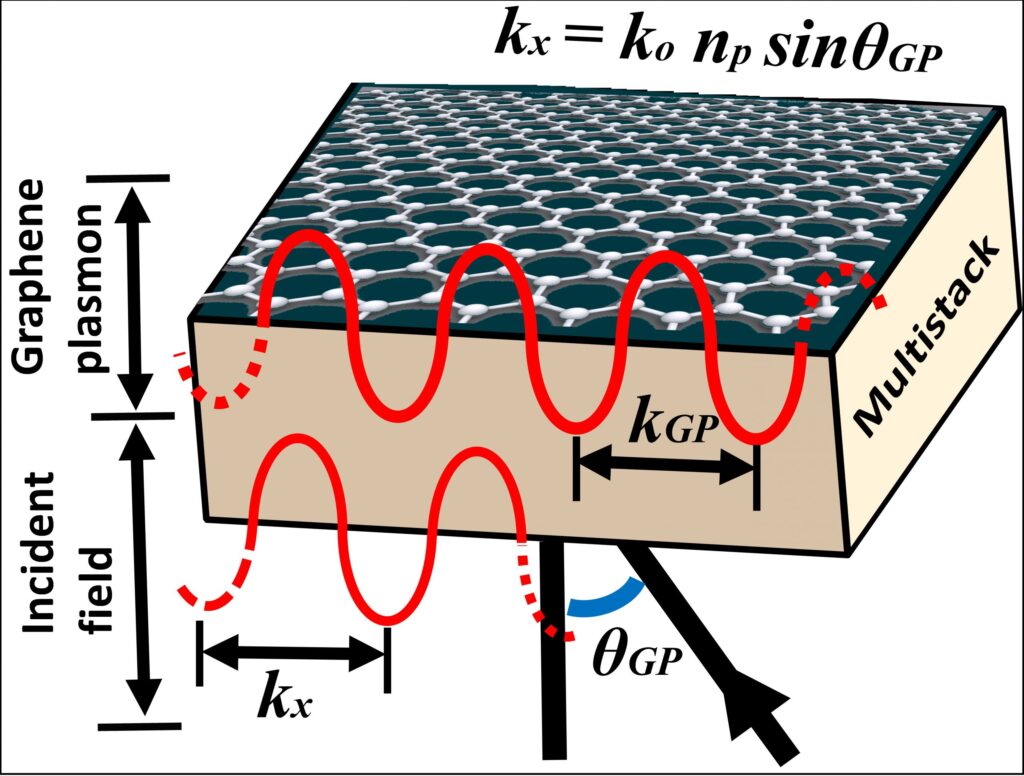

- The nanophotonic performance of the multistack was analyzed and successfully demonstrated to realize ‘graphene oxide plasmon-coupled soliton emission’ (abbreviated as GraSE) with steering/beaming emission characteristic as well as ‘graphene oxide plasmon-coupled emission’ (abbreviated as GraPE) with directional property

- Since both beaming GraSE and directional GraPE could be captured in a single platform, the combination led to the birth of GraSP emission platform

- An everyday example of soliton is a self-sustaining water bubble that maintains its shape as it moves, all the way from the bottom of the tank to the surface, in completely still water. Similar solitons transporting emitted photons in GraSP platform are successfully demonstrated in this research work for augmented sensor performance.

- GraSP can now simplify the existing surface plasmon resonance (SPR) technology with enhanced performance

Key Features and Benefits

- Use of non-metal platform to avoid Ohmic loss

- GraSP improves the overall sensitivity and specificity by 3-4 times as compared to existing metal-dependent sensor techniques

- The extreme light entrapment and augmentation via hotspots from surface states and nanoscopic volumes aided in lowering the detection limit of the HuIFN-γ antigen to 1.95 pg mL−1, for superior performance in resource limited settings

- GraSP platform is useful in disease diagnostics in early stages of disease conditions and also help in the advancement of Point-of-Care (POC) devices

Impact

- A simple, user-friendly, cost-effective methodology is adopted to realize GraSP engineering with soliton-aided metal analogues and directional emission patterns on a conventional existing sensor technology based on plasmonic platform

- The subject platform is expected to find immediate deployment for real-time point-of-care medical diagnostics. It is strongly believed that this study presents a stepping stone to a plethora of exciting plasmonic architectures and disruptive diagnostics in near future.

- An industry or market seeking such devices with augmented sensitivity could take forward the proposed methodology for utility in early disease diagnostics, environmental safety and industrial applications

- GrasP is especially beneficial for low- and middle-income countries

Team

Seemesh Bhaskar, Naga Sai Visweswar Kambhampati, K. M. Ganesh, Mahesh Sharma P, Venkatesh Srinivasan, and Sai Sathish Ramamurthy. STAR Laboratory, Department of Chemistry, Sri Sathya Sai Institute of Higher Learning, Prasanthi Nilayam, Puttaparthi, Anantapur, Andhra Pradesh 515134, India.

Paper Published In: ACS Applied Matter Interfaces.

Read Paper Here: https://pubs.acs.org/doi/10.1021/acsami.1c01024

Sri Sathya Sai Institute of Higher Learning, India, to Collaborate with Sweden’s Uppsala University for ‘Bio-Materials Research’

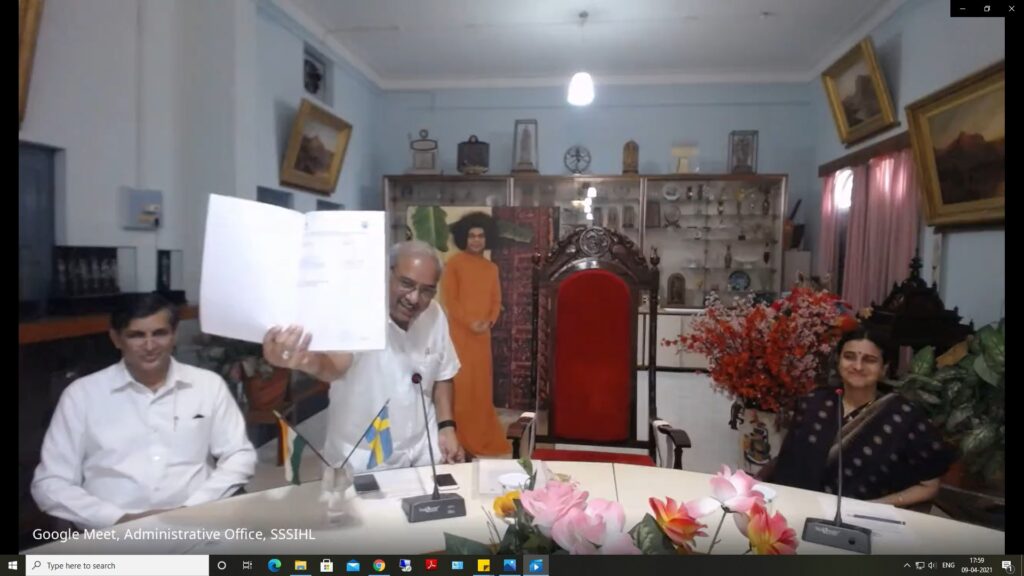

Puttaparthi, 9 April 2021: Sri Sathya Sai Institute of Higher Learning (Deemed-to-be University), Puttaparthi, Andhra Pradesh, today entered into a research collaboration agreement with Uppsala University, Sweden, in the area of ‘Bio-Materials Research.’

The agreement was signed by Prof. B. Sai Giridhar, the Registrar, on behalf of Sri Sathya Sai Institute of Higher Learning (SSSIHL) and Prof. Åsa Kassman, Chairperson, Department of Material Science and Engineering, Uppsala University. H.E. Shri Tanmaya Lal, the Indian Ambassador to Sweden, presided over the event, along with Prof. (Dr.) C. B Sanjeevi, the Vice-Chancellor of the Sri Sathya Sai Institute of Higher Learning, Puttaparthi.

The collaboration will see both Uppsala University and Sri Sathya Sai Institute of Higher Learning leverage each other’s skills and research capabilities in the areas of bio-materials, leading to the development of dental and bone implants with the objective of harnessing its translational potential. This research will be led by Dr. (Ms.) Deepa Seetharaman, Principal Investigator (PI) for the SSSIHL, India, and Dr. Håkan Engqvist, (PI) for Uppsala University, Sweden.

This research collaboration is an important and prestigious landmark for the Sri Sathya Sai Institute of Higher Learning. Hence, we dedicate this partnership to Sri Sathya Sai Baba, the Revered Founder Chancellor, SSSIHL, on whose guiding principles the institute was conceived as a Modern Gurukula.

About Uppsala University

Founded in 1477, Uppsala University is Sweden’s oldest university – well known for famous alumni scientists and inventors of the likes of Carl Linnaeus, Anders Celsius, to name a few and over 15 Nobel Laureates. Ranked 111 (THE Ranks) in the list of the world’s best universities in 2021, Uppsala University is a comprehensive research-intensive university with a strong international standing, with an ultimate objective to conduct education and research of the highest quality and relevance while making a long-term difference in society. The University has over 50,000 students, more than 7,000 employees, and a turnover of around SEK 7 billion, offering 39 different masters programmes, covering over 60 different specializations, and driving “Quality, Knowledge, and Creativity for a better world.”

About Sri Sathya Sai Institute of Higher Learning

The Sri Sathya Sai Institute of Higher Learning (SSSIHL) (Deemed-to-be-University), Prasanthi Nilayam, is one of the few institutions in the world offering values-based quality education free of charge to the students at the university level. Ethics and morals form the undercurrent of every subject taught at the university, providing a holistic framework of inter-personal development for its students combined with academic excellence. This year, we celebrate the commencement of the University’s 40th year of excellence.

The Sri Sathya Sai Institute of Higher Learning (SSSIHL) also provides a strong research environment, with exceptional academic practices, that has resulted in the growth of national and international collaborations. The Central Research Instruments Facility (CRIF), based at the Prasanthi Nilayam Campus of the SSSIHL, is one of the few facilities in the country that houses advanced Characterisation/ Analytical Tools to carry out Translational Research in various areas of Science and Technology.

For more Information, contact:

Prof. B. Sai Giridhar, Registrar, SSSIHL, email: [email protected]; Tel: +91 8555287239

Dr. Håkan Engqvist, PI, Uppsala University, email: [email protected]

Tel: +46-70-2569500